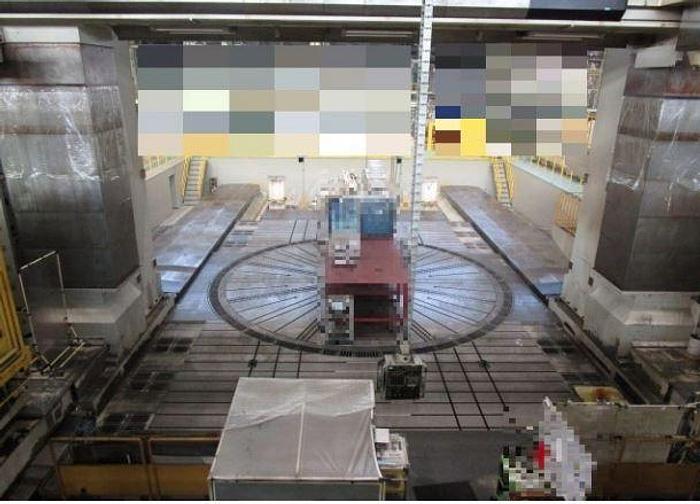

Homma HMT-8/10 GTN CNC Heavy Duty Gantry Type Double Column Milling Machine / Vertical Turning Mill

Homma HMT-8/10 GTN CNC Heavy Duty Gantry Type Double Column Milling Machine / Vertical Turning Mill

or

Call 770-509-0744

Description

Fanuc-30i CNC Control System Automatic Milling Tool Changer ISO 60 : 10 – ISO 50 : 10 Tilt Attachment ISO 50 A & B axis Control Offset Snout ISO 50 Offset Value 225 mm 3 x Turning Heads Automatic Attachment Changing Function for 10 attachments Coolant Unit (Including Air Blow Function) High & Low Pressure Switching Type (C-Axis) CNC Vertical Boring Mill Table 8000 mm dia. Operator Platform Chip Conveyors Hinge Belt Type Closed Loop Control System X, Y, Z, W, A, C Axis Tool Length Measurement: For Turning Tools Operator Platform : Fixed to Both Side Column Base Pendant Control Box : Up/Down Right/Left By Electric Powered

Specifications

| Manufacturer | Homma |

| Model | HMT-8/10 GTN |

| Year | 2011 |

| Condition | Used |

| Stock Number | 10913 |

| Table diameter | 8,000 mm |

| Swing | 10,000 mm |

| Turning height | 7,200 mm |

| Table capacity | 250 Ton |

| Live spindle speed | 1,600 rpm |

| Gantry travel | 15,000 mm |

| Z axis travel | 3,000 mm |

| X axis travel | +7,000 mm - 8,000 mm |

| Y axis travel | 11,300 mm |

| W axis travel | 4,200 mm |

| Distance between columns | 10,000 mm |

| Table indexing minimum increment | 0.0001 Degree |

| Table drive system | Double Worm, Double Pinion Gear Drive |

| Rapid traverse rate table | 180 deg/min |

| Feed rate of table | 1 - 180 deg.min |

| Feed rate x axis | 1 - 5,000 mm/min |

| Table clamping force | 49,000 Nm - 5,000 kg/m |

| Table position detector | Heidenhain 786 Rotary Encoder |

| Index control system | Hybrid Controlled Closed Loop |

| Table clamping method | Hydraulic Disc Brakes |

| Rapid traverse x axis | 8,000 mm/min |

| Drive system | Precision Rack & Pinion |

| X axis position detector | Heidenhain Optical C Scale |

| Main head ram type | 650 x 650 mm |

| Spindle drive capacity | AC 100 kW |

| Spindle diameter (snout) | 220 mm |

| Milling spindle taper | ISO 60 |

| Machine height above floor | 16,000 mm |

| Floor space required | 28 x 20 m |