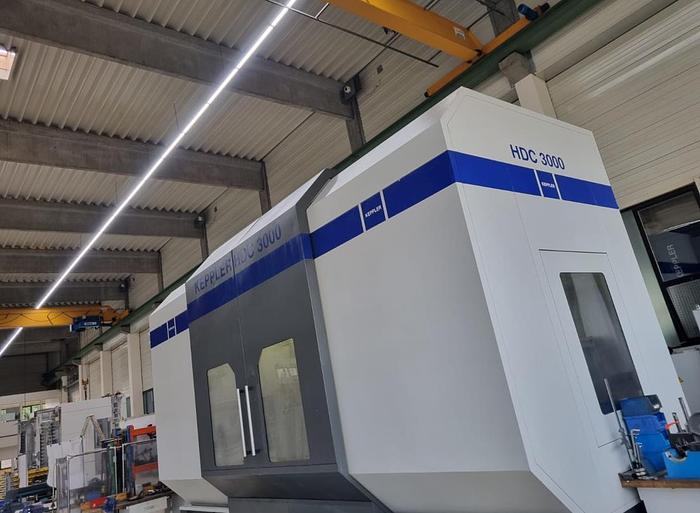

Keppler HDC 3000 CNC 5-Axis Universal Machining Center

Keppler HDC 3000 CNC 5-Axis Universal Machining Center

Description

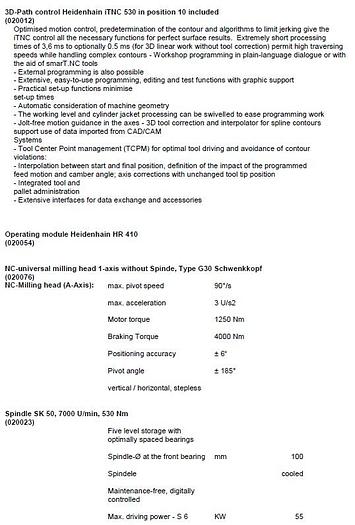

Heidenhain iTNC 530 CNC Control – 3D Path Control in Position 10

Optimised motion control, predetermination of the contour and algorithms to limit jerking give the iTNC control all the necessary functions for perfect surface results. Extremely short processing times of 3,6 ms to optionally 0.5 ms (for 3D linear work without tool correction) permit high traversing speeds while handling complex contours - Workshop programming in plain-language dialogue or with the aid of smarT.NC tools

- External programming is also possible

- Extensive, easy-to-use programming, editing and test functions with graphic support

- Practical set-up functions minimise set-up times

- Automatic consideration of machine geometry

- The working level and cylinder jacket processing can be swivelled to ease programming work

- Jolt-free motion guidance in the axes - 3D tool correction and interpolator for spline contours support use of data imported from CAD/CAM Systems

- Tool Center Point management (TCPM) for optimal tool driving and avoidance of contour violations:

- Interpolation between start and final position, definition of the impact of the programmed feed motion and camber angle; axis corrections with unchanged tool tip position

- Integrated tool and pallet administration

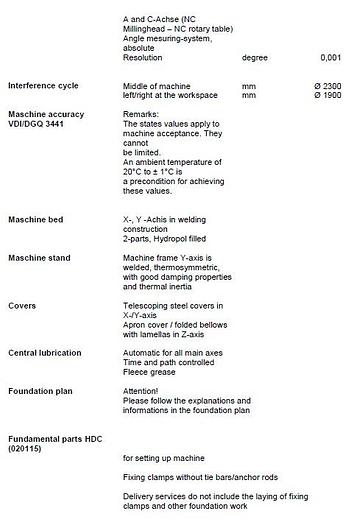

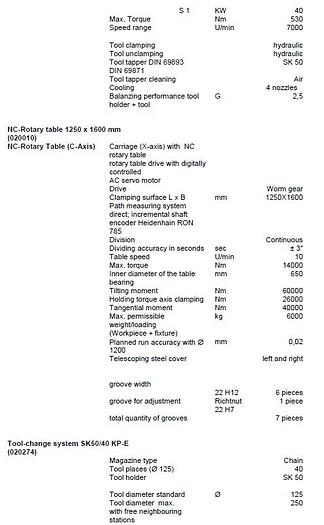

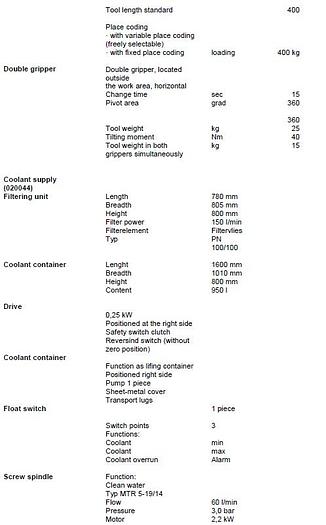

- Extensive interfaces for data exchange and accessories - Heidenhain HR 410 Operating Module NC Universal Milling Head 1-Axis without Spindle Type Spindle SK50 7,000 rpm NC Rotary Table 1,250 x 1,600 mm X,Y,Z Axes Linear Roller Guides, Central Lubrication X,Y,Z Axes Precision Ball Thread Gears Full Enclosure

Worm Gear Drive 40 Position Automatic Tool Changer Coolant Supply

Hydraulic Tool Clamping - Unclamping Internal Coolant Supply (IKZ) 60 bar

4 Nozzle Cooling

External Blowing Unit (Air)

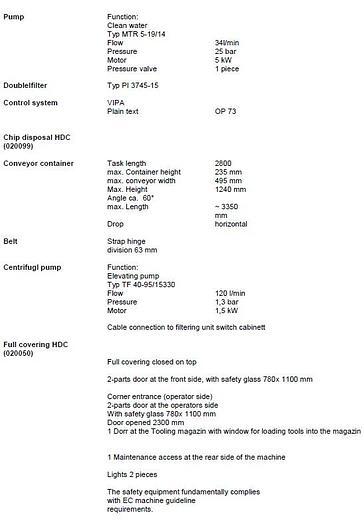

Internal Blowing Unit (Air) Wash Gun 3-D Measuring Probe Chip Conveyor

Kinematics Option Documentation

Specifications

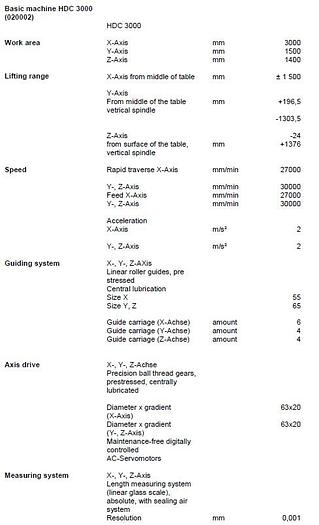

| Manufacturer | Keppler |

| Model | HDC 3000 |

| Year | 2015 |

| Condition | Used |

| Stock Number | 11021 |

| Spindle speeds | 7,000 rpm |

| X axis travel | 3,000 mm |

| Y axis travel | 1,500 mm |

| Z axis travel | 1,400 mm |

| NC rotary table dimensions | 1,250 x 1,600 mm |

| X axis from middle of table | ± 1,500 mm |

| Y axis from middle of table vertical spindle | + 196.5, -1,303.5 mm |

| Z axis from table surface vertical spindle | -24, +1,376 mm |

| Rapid traverse x axis | 27,000 mm/min |

| Rapid traverse y,z axes | 30,000 mm/min |

| Max pivot speed | 90°/s |

| Max acceleration | 3 U/s2 |

| Motor torque | 1250 Nm |

| Braking torque | 4000 Nm |

| Positioning accuracy | ±6" |

| Pivot angle | ± 185° |

| Tool tpaer | SK 50 |

| Spindle torque | 530 Nm |

| Spindle diameter at front bearing | 100 mm |

| Max driving power - s6 | 55 kW |

| Max driving power - s1 | 40 kW |

| Table speed | 10 rpm |

| Max torque | 14000 Nm |

| Inner diameter of table bearing | 650 mm |

| Tilting moment | 60000 Nm |

| Holding torque axis clamping | 26000 Nm |

| Tangential moment | 40000 Nm |

| Max permissible weight | 6 M Ton |

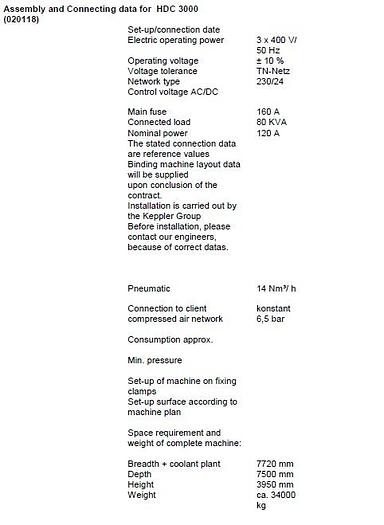

| Electric operating power | 3 x 400V / 50 HZ |

| Operating voltage | ±10% |

| Main fuse | 160 A |

| Nominal load | 120 A |

| Connected load | 80 KVA |

| Depth x height | 7,500 x 3,950 mm |

| Breadth & coolant plant | 7,720 mm |

| Machine weight | 34 M Ton |